Tlhaloso e phahameng ea Plastic Recycling Granulating Line/Waste Film Recycling Pelletizer Machine

Rea tseba hore re atleha ha feela re ka netefatsa tlholisano ea rona ea theko e kopaneng le boleng ba boleng bo holimo ka nako e le 'ngoe bakeng sa Tlhaloso e Phahameng ea Plastic Recycling Granulating Line/Waste Film Recycling Pelletizer Machine, Ho tšepa bareki ba hapileng e tla ba senotlolo sa khauta seo re se finyeletseng!Haeba u ka khahloa ke thepa ea rona, u lokela ho ba le monyetla oa ho ea webosaeteng ea rona kapa u ikopanye le rona.

Rea tseba hore re atleha ha feela re ka netefatsa tlholisano ea rona ea theko e kopaneng le boleng ba boleng bo holimo ka nako e le 'ngoe bakeng saChina li-satges tse peli tsa Extruder le Plastic Extrusion Machinery, Re lumela ka tieo hore theknoloji le tšebeletso ke motheo oa rona kajeno le boleng bo tla theha marako a rona a ka tšeptjoang a bokamoso.Ke rona feela re nang le boleng bo betere le bo betere, re ka fihlelang bareki ba rona le rona ka borona.Amohela bareki hohle ka lentsoe ho ikopanya le rona bakeng sa ho fumana khoebo e eketsehileng le likamano tse tšepahalang.Haesale re le mona re sebeletsa litlhoko tsa hau neng kapa neng ha u hloka ho ba le.

Video ea Sehlahisoa:

Ntlafatso ea Litšoantšo:

Sesebediswa:

HDPE, LDPE, LLDPE, PP, joalo ka lifilimi, mekotla, li-flakes, lirolara tsa lifilimi, filimi e otlolohileng, filimi e honyehang, filimi e nang le likarolo tse ngata, mekotla e sehiloeng ea T-shirt.

PE e Foamed, EPS le XPS: meqolo, mokotla, lakane, sejana sa lijo, letlooa la litholoana, sekoaelo

Textile: PP fiber, raffia, silika, khoele, mokotla o lohiloeng, mokotla oa jumbo

Likaroloana:

Sistimi ena e kopaneng ea compactor ea pelletizing e ruisa thepa e nchafalitsoeng ntle le ho seha pele

Compacting e na le li-valve tsa seha, tse sebelisetsoang ho laola lebelo la ho fepa

Vacuum system ea ho ntša metsi kapa khase ka bongata bo boholo

Sesefa se setle sa hydraulic screen se nang le khatello e tsitsitseng bakeng sa ho se emise, ha ho dutla

Ho boloka matla ka tlhahiso e phahameng (0.28kwh/kg)

Mokhoa o akaretsang oa ts'ebetso:

1.Belt conveyor fetisetsa lintho tse bonahalang ka shredding compactor.

2.The interlock tsamaiso ea pakeng tsa lebanta fetisa ho le shredding compactor etsa bonnete ba ho leka-lekana fepa ntle melted compactor.

3.Botlaaseng ba shredding compactor, ho na le boto e le 'ngoe ea seha.ka matla a centrifugal, lisebelisoa tse recycled li fumana ho sehoa esale pele ke li-cutters tse ka hare tsa rotary le li-stationary cutters.

4.Ka mor'a moo, thepa e kena ka har'a sekoti sa degassing ho tloha lehlakoreng la compactor.

5.Ka ho futhumala ha screw, polasetiki e fetoha thepa ea semi-plastification.

6. 'Me joale, thepa ea semi-plastiki e khaola li-pellets.

Parameter e ka sehloohong ea tekheniki:

| Mohlala | ML75 | ML85/SJ90 | ML100/SJ120 | ML130/SJ140 | ML160/SJ180 | ML180/SJ200 |

| Screw bophara(mm) | 75 | Mohato oa pele 85Mohato oa bobeli oa 90 | Mohato oa pele 100Mohato oa bobeli oa 120 | Mohato oa pele:130Mokhahlelo oa Bobeli:140 | Mohato oa pele:160Mokhahlelo oa Bobeli:180 | Mohato oa pele:180Mohato oa bobeli:200 |

| L/D | Mohato oa pele: 26 ho isa ho 37Mohato oa Bobeli:10 ho isa ho 15 | |||||

| Sephetho(kg/h) | 100-150 | 200-350 | 400 ho isa ho 550 | 600 ho isa ho 800 | 800 ho isa ho 1000 | 1000-1200 |

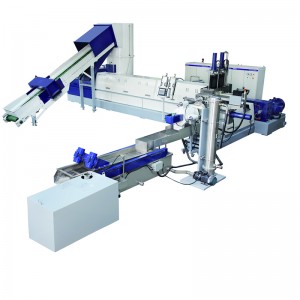

Litšoantšo tsa mochini:

Sesebelisoa se le seng sa screw extruder

Methati e 'meli ea ho recycle extruder

Lintlha tse akaretsang:

| Lebitso la mohlala | ML |

| tlhahiso | Li-pellets tsa polasetiki / li-granules / resin / thepa e tala ea polasetiki |

| Likarolo tsa mochini | Lebanta conveyor, cutter compactor, main extruder, pelletizing unit, cooling system, silo, cabinet |

| Lintho tse sebelisoang hape | PP/PE/LDPE/HDPE filimi, mokotla, fiber |

| Sebaka sa bokhoni | 100kg/h ho isa ho 1200kg/h |

| Mokhoa oa ho fepa | Conveyor, tsamaiso ea ho khanna |

| Screw diameter | 75mm ho isa ho 200mm |

| Screw L/D | 26 ho isa ho 33 |

| Screw thepa e tala | 38CrMoAl kapa bimetallic |

| degassing | Ho tlosa gase ka tlhaho, ho tlosa metsi ka vacuum |

| Mofuta oa ho khaola | E otlolohileng pelletizing tsela, hula strip pelletizing |

| Mofuta o phodileng | Metsi a pholile, moea o pholile |

| Palo ea li-volts | Customized |

| Lisebelisoa tsa boikhethelo | Sesebelisoa sa tšepe, sistimi ea ho pholisa metsi, silo ea ho fepa, sistimi ea vibration |

| Nako ea thomello | Matsatsi a 40 ho isa ho a 60 |

| Nako ea tiisetso | Likhoeli tse 13 |

| Litšehetso tsa tekheniki | Sebopeho sa mochini, sebopeho sa ho kenya, tšebeletso ea moenjiniere mose ho maoatle |

| Setifikeiti | CE/ SGS/TUV/CO |

Ke hobane'ng ha u re khetha?

A.PURUI e na le moetsi oa litsebi ho tloha 2006. re na le lefapha la rona la meralo ea theknoloji.E mong le e extruder fumana etselitsoe ho ea ka thepa tšobotsi.

B.Ho boloka matla ka tlhahiso e phahameng

C. Nako ea tiisetso ea boleng ke likhoeli tse 12 ho tloha ka letsatsi la Bill of Lading.

D. Nako ea ho fana: matsatsi a mosebetsi a 40 ho isa matsatsing a 60

E.Ship e kopiloeng sephutheloana

Ho kenngoa ha F. Machine ho teng.Ho nka matsatsi a ka bang 5 ho isa ho a 7 ka ho qeta nako e le 'ngoe ea ho kenya.Moenjiniere (ba) o laola koetliso ea mosebelisi oa mochini, ts'ebetso ea mochini le khomishene.

Selelekela sa Khampani:

Chengdu PuRui Polymer Engineering Co. Ltd ke e mong oa baetsi ba ka sehloohong ba mechine ea polasetiki ea ho tsosolosa, extruder, granulator ea polasetiki le lisebelisoa tse thusang tse amanang le tsona Chaena.Melemo e ikhethang ea sistimi ea rona ea polasetiki ke moralo oa screw, tlhahiso e phahameng, degassing e ntle le phello e ntle ea filthara.Mohala oa rona oa ho hlatsoa polasetiki o kang crusher e nang le khanyetso e mamellehang le sehahi se bohale, lisebelisoa tse hlatsoang, mochini o arolang kapa oa ho hlopha, mochini o omisang, le sistimi ea ho paka ke tsa boleng bo holimo. molemo ka nako e le 'ngoe bakeng sa Tlhaloso e Phahameng ea Plastic Recycling Granulating Line/Waste Film Recycling Pelletizer Machine, Ho tšepa bareki ba hlōlang e tla ba senotlolo sa khauta seo re se finyeletseng!Haeba u ka khahloa ke thepa ea rona, u lokela ho ba le monyetla oa ho ea webosaeteng ea rona kapa u ikopanye le rona.

Tlhaloso e phahameng ea China Twin Screw Extruder le Plastic Extrusion Machinery, Re lumela ka tieo hore theknoloji le tšebeletso ke motheo oa rona kajeno mme boleng bo tla theha marako a rona a ka tšeptjoang a bokamoso.Ke rona feela re nang le boleng bo betere le bo betere, re ka fihlelang bareki ba rona le rona ka borona.Amohela bareki hohle ka lentsoe ho ikopanya le rona bakeng sa ho fumana khoebo e eketsehileng le likamano tse tšepahalang.Haesale re le mona re sebeletsa litlhoko tsa hau neng kapa neng ha u hloka ho ba le.

Mochini oa polasetiki o recycleng le oa granulating ke mofuta oa lisebelisoa tse sebelisoang ho khutlisetsa litšila tsa polasetiki ho li-granules kapa li-pellets tse ka sebelisoang hape ho etsa lihlahisoa tse ncha tsa polasetiki.Hangata mochini o sebetsa ka ho petsola kapa ho sila litšila tsa polasetiki hore li be likotoana tse nyane, ebe oa qhibiliha ebe oa li ntša ka lefi ho etsa li-pellets kapa granules.

Ho na le mefuta e fapaneng ea metjhini e nchafatsang ea polasetiki le ea granulating e fumanehang, ho kenyeletsoa screw le li-twin-screw extruder.Mechini e meng e boetse e kenyelletsa likarolo tse ling tse kang li-skrini ho tlosa litšila ho litšila tsa polasetiki kapa mekhoa ea ho pholisa ho netefatsa hore li-pellets li tiisitsoe hantle.Mochini oa ho hlatsoa botlolo ea PET, PP e lohiloeng ka mekotla ea ho hlatsoa mohala

Mechini e nchafatsang polasetiki le ea granulating hangata e sebelisoa liindastering tse hlahisang litšila tse ngata tsa polasetiki, joalo ka ho paka, likoloi le kaho.Ka ho tsosolosa litšila tsa polasetiki, mechine ena e thusa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha polasetiki le ho boloka lisebelisoa ka ho sebelisa thepa e neng e tla lahloa.

Thepa ea li-betri tsa lithium ke mofuta oa lisebelisoa tse sebelisetsoang ho khutlisa le ho khutlisa lisebelisoa tsa bohlokoa ho tsoa libetering tsa lithium-ion, tse sebelisoang hangata lisebelisoa tsa elektroniki tse kang li-smartphone, lilaptop le likoloi tsa motlakase.Thepa hangata e sebetsa ka ho pshatla libeteri likarolong tsa tsona, joalo ka lisebelisoa tsa cathode le anode, tharollo ea electrolyte le lithapo tsa tšepe, ebe li arola le ho hloekisa lisebelisoa tsena hore li sebelisoe hape.

Ho na le mefuta e fapaneng ea lisebelisoa tsa ho nchafatsa betri ea lithium tse fumanehang, ho kenyelletsa lits'ebetso tsa pyrometallurgical, lits'ebetso tsa hydrometallurgical, le lits'ebetso tsa mochini.Ts'ebetso ea pyrometallurgical e kenyelletsa ts'ebetso e phahameng ea mocheso oa libeteri ho khutlisa litšepe tse kang koporo, nickel le cobalt.Ts'ebetso ea Hydrometallurgical e sebelisa tharollo ea lik'hemik'hale ho qhala likarolo tsa betri le ho khutlisa litšepe, ha lits'ebetso tsa mochini li kenyelletsa ho pshatla le ho sila libeteri ho arola lisebelisoa.

Thepa ea ho sebelisa betri ea lithium e bohlokoa bakeng sa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha betri le ho baballa lisebelisoa ka ho khutlisa litšepe tsa bohlokoa le lisebelisoa tse ka sebelisoang hape ka libeteri tse ncha kapa lihlahisoa tse ling.

Ntle le melemo ea ho boloka tikoloho le lisebelisoa, lisebelisoa tsa ho sebelisa betri ea lithium le tsona li na le melemo ea moruo.Ho fumana litšepe tsa bohlokoa le lisebelisoa ho tsoa libetering tse sebelisitsoeng ho ka fokotsa litšenyehelo tsa ho hlahisa libeteri tse ncha, hammoho le ho theha mekhoa e mecha ea chelete bakeng sa lik'hamphani tse amehang ts'ebetsong ea ho e sebelisa hape.

Ho feta moo, tlhokahalo e ntseng e eketseha ea likoloi tsa motlakase le lisebelisoa tse ling tsa elektroniki e tsamaisa tlhokahalo ea indasteri e sebetsang hantle le e tsitsitseng ea ho sebelisa li-betri.Thepa ea ho sebelisa betri ea lithium e ka thusa ho fihlela tlhoko ena ka ho fana ka mokhoa o tšepahalang le o theko e tlase oa ho khutlisa lisebelisoa tsa bohlokoa libetering tse sebelisitsoeng.

Leha ho le joalo, ho bohlokoa ho hlokomela hore ho sebelisa betri ea lithium e ntse e le indasteri e ncha, 'me ho na le liphephetso tse lokelang ho hlōloa mabapi le ho theha mekhoa e sebetsang hantle le e bolokang chelete e ngata.Ho feta moo, ts'ebetso e nepahetseng le ho lahla litšila tsa betri ho bohlokoa ho qoba likotsi tsa tikoloho le bophelo bo botle.Ka hona, melaoana e nepahetseng le mehato ea polokeho e tlameha ho ba teng ho netefatsa ts'ebetso e nang le boikarabelo le ho tsosolosoa ha libeteri tsa lithium.