-

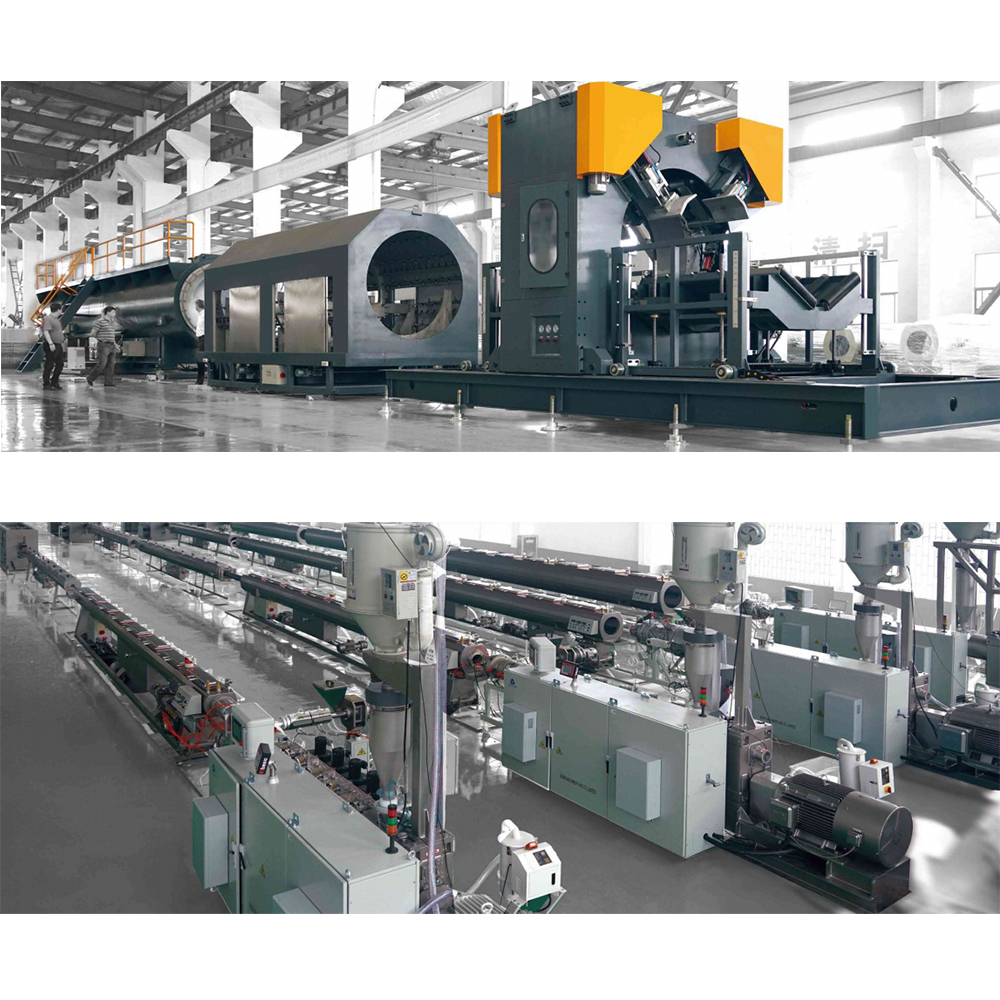

Mochini oa extrusion oa lipeipi tsa PE

Mochini oa extrusion oa PE

Mochini o ka sehloohong ke oa extrusion ea pipe ea PE, matla a 400-450kg ka hora.E loketse bophara ba PEpipe 50-200mm.

bophara ba extruder: 60mm,

Boemo:4200×1350×2600(mm)(Bolelele*Bophara*bophara)

Boima ba mochini oohle:3500(kg)

Mofuta oa ho futhumatsa: ceramic+k'hothone ea insulation

Sebaka sa ho futhumatsa: 5(likarolo)

Matla a futhumatsang:3.6(kw)×4 likotoana+3.0(kw)×1sengoathoana

Taolo ea mocheso:50-300(℃)

Re atolositse sebaka sa rona sa lihlahisoa.Sebakeng sa extrusion, re na le phihlelo e ngata.Ho fumana lintlha tse ling, ka kopo ikutloe u lokolohile ho ikopanya le rona.

-

Corner board mochini oa extrusion oa polasetiki bakeng sa lisebelisoa tse hloekileng tsa PP le PE

Corner board mochini oa extrusion oa polasetiki bakeng sa lisebelisoa tse hloekileng tsa PP le PE

Lihlahisoa tse ncha tse kopanetsoeng tse etselitsoeng ho etsa liprofaele tsa boto ea likhutlo.Matla a ka bang 150kg/h.E ka thusa moreki ho sebelisa lipolasetiki tsa PP le tsa PE tse nchafalitsoeng kapa tse boeleng ho hlahisa lipolasetiki tse ncha.E na le

1) Vacuum loader ka ho omisa hopper 1set;

2) 75 single screw extruder 1set;

3) 4.8meters vacuum shaping tafole 1set;

4) Mochini oa ho hula le oa ho itšeha mofuta o felletseng oa 1set;

5) Ho lahla stacker 1 sete;

6) Khabinete e ka sehloohong ea motlakase 1set.

7) Shoela hlobo

8) Sekoti se le seng sa co-extruder

9) 5HP metsi chiller

10) Plastic crusher bakeng sa ho sebelisoa hape

Mechini eohle e thusang e fumaneha.

-

Mochini oa ho etsa lipeipi tsa PVC

Re sebelitse le lik'hamphani tse tummeng tsa lipeipi tsa China le extruder ho qala letoto la lisebelisoa tsa extrusion:

1.PPR,PP,PE pipe extruder

2.Multi-layer PPR tube extruder

3.PVC phala extruder

4.PVC Exextruder

5.WPC Mochini oa Lehong-Plastiki

6.PET lakane extruder

7.PC PMMA PSMS-chip extruderThepa e romelloa linaheng tse 70 lefatšeng ka bophara, ka mokhoa o tsitsitseng oa ho rekisa ka mor'a ho rekisoa le tšehetso e matla ea sehlopha sa theknoloji, re ka u fa mefuta e mengata ea tharollo le lisebelisoa tse feletseng.

PPR e ka sebelisoa bakeng sa ho futhumatsa fatše, ho futhumatsa bohareng ba bolulo le indasteri, lipalangoang tsa indasteri (linoa tsa lik'hemik'hale le likhase), lipalangoang tsa metsi a nooang, lisebelisoa tse khethehileng, lipalangoang tsa metsi a chesang le a batang.