Khetho e Khōlō bakeng sa Mochini o Hlatsoang Lifilimi oa China o Hlatsoang le ho Hlōla

Re ikemiselitse ho arolelana tsebo ea rona ea papatso lefats'eng ka bophara mme re u khothaletsa thepa e loketseng ka litheko tse matla haholo tsa thekiso.Kahoo Profi Tools e u tlisetsa theko e ntle ka ho fetisisa ea chelete 'me re ikemiselitse ho hlahisa hammoho le Massive Selection bakeng sa Mochini oa ho Hlatsoa Letlapa la China o Hlatsoang le ho Hlōla, Re na le ts'epo ea hore re ka fana ka lihlahisoa tsa boleng bo holimo ka theko e tlase, ts'ebeletso e ntle ka mor'a thekiso. ho bareki.'Me re tla theha bokamoso bo khanyang.

Re ikemiselitse ho arolelana tsebo ea rona ea papatso lefats'eng ka bophara mme re u khothaletsa thepa e loketseng ka litheko tse matla haholo tsa thekiso.Kahoo Profi Tools e u fa theko e ntle ka ho fetisisa ea chelete mme re ikemiselitse ho e hlahisa hammoho leChina Plastic Granulator, Mochini oa Granulating oa Filimi ea litšila, Khamphani ea rona e thehile likamano tse tsitsitseng tsa khoebo le lik'hamphani tse ngata tse tsebahalang tsa malapeng hammoho le bareki ba mose ho maoatle.Ka sepheo sa ho fana ka lintho tsa boleng bo holimo ho bareki ba li-cots tse tlase, re ikemiselitse ho ntlafatsa bokhoni ba eona ho lipatlisiso, nts'etsopele, tlhahiso le tsamaiso.Re motlotlo ho fumana kananelo ho tsoa ho bareki ba rona.Ho fihlela joale re fetile ISO9001 ka 2005 le ISO/TS16949 ka 2008. Likhoebo tsa "boleng ba ho phela, botšepehi ba tsoelo-pele" ka morero, li amohela ka tieo bo-rakhoebo ba malapeng le ba tsoang linaheng tse ling ho etela ho buisana ka tšebelisano.

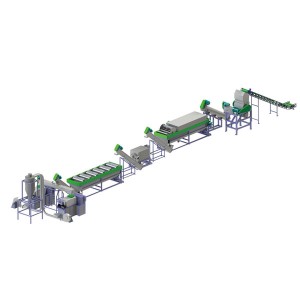

Mohala oa ho Hlatsoa Lifilimi tsa Post-Temo PE

Ho itšeha filimi ea polasetiki, ho hlatsoa, mochini o sebelisoang hape o nang le tlhahiso e phahameng le bokhoni bo botle bo hloekileng (500kg / h ho isa 6500kg / h)

Mohala oohle oa polasetiki o sebelisetsoa ho sila, ho hlatsoa, ho ntša metsi le ho omisa filimi ea PP/PE, mokotla o lohiloeng oa PP.

Lisebelisoa:

Mohala ona oa ho hlatsoa o ka sebelisoa bakeng sa mokotla o lohiloeng oa PP, filimi le mokotla oa lithōle oa PE, filimi, thepa ea ho paka le lintho tse ling tse hlephileng, filimi ea temo (1mm), filimi ea indasteri ea LDPE e nang le lebese le phofo, filimi ea ntlo e tala ea LDPE.

Mokhoa oa ho sebetsa:

Belt conveyor-crusher-spiral feeder-friction washer-spiral feeder-floating tank-spiral feeder (upload)-spiral feeder (download)-hot washer-friction washer-spiral feeder-floating tank-spiral feeder-centrifugal dewatering-pipe dryer- silo

Kenyelletso ea likarolo tsa mochini:

| Bale Breaking | Ho thusa ho tsamaisa lifilimi, morekisi ea ntseng a eketseha oa litšila tsa polasetiki o khetha ho hatella filimi hore e be beile.Kaha recycler o ile a etsa recycling polasetiki, ba hlokaBreak the bale.Hydraulic CutterKa ho kenya bale kaofela, seha sehateroli se seha likotoana tse nyane.Pre-shredderHo pshatla beile ka shaft e ka hare e nang le sekhechana se selelele |

| Cho potlaka | Plastiki Granulator/crusher ho tswela pele ho seha matlakala a malelele hore e be sekotoana se senyane sa moqomo o metsi o na le litlamorao tse 2Ka lehlakoreng le leng, ho hlatsoa makumane a pshatlehileng ka metsi, ka lehlakoreng le leng, metsi a ka fokotsa mocheso ka li-crusher cutters(bere-resistance) Crusher e ka hlomelloa. e nang le platelete ea ho sebetsaE sebetsoa habonolo ka li-cutters tse hlabang |

| Ho hlatsoa pele | Pre-washer Mochine ona ke haholo-holo bakeng sa ho hloekisa filimi ea polasetiki ea PE / PP / PET le li-flakes tseo ka mor'a ho senya, ho hloekisa litšila tse kopantsoeng filiming.Li-shaft tse peli tse ka hare tse kholo tse potolohang ka tanka e potolohang, thepa e tla be e phaphatha le ho hlatsoa ka. ho arola litšila tse mamarelang.Mochini o hlatsoang pele lifilimi (li-shafts tse peli tse bilikang) Moralo o khethehileng oa lehare la ho fepa le ho hlatsoa filimi ea boholo bo boholo pele ho hlatsuoa, skrineng se ka tlosa boholo ba lehlabathe le litšila le 99%.E ka sireletsa lithipa tsa crusher hore li sebetse nako e telele le ho sebetsa hantle haholoanyane.Filimi ea litšila ka mochini o hlatsoang pele o ka fokotsa litšila ka 80%.Mochine o ka ba metsi le ho omella ho hlatsoa.Trommelwith roll drum e potoloha ka potlako, litšila tse kholo li tla sefa ka lesoba la moqomo.Litšila tse kholo li tla fetisoa ka lebanta le ka tlase la conveyor. |

| Ho hlatsoa | Tanka e phaphametseng Hlatsoa 'me u arole lisebelisoa ka matla a khoheli le matla a khoheli a metsi. Ho boloka metsi ka ho sebelisa ketane ea tšepe e sa hloekang, le valve ea ho bula moea. |

| Ho nosetsa | Horizontal Centrifugal DryerMochini ona o sebelisoa haholo-holo ho hloekisa filimi ea polasetiki e hloekisang, matla a centrifugal ho tloha ho potoloha ka lebelo le phahameng bakeng sa master shaft e lahlelang filimi ea polasetiki le metsi khahlanong le skrine, 'me metsi a ntšoa skrineng.Mochine ona o sebetsa hantle ho omisa le ho sebetsa hantle haholo.Se omisa lipeipiKa moea o chesang ka liphaephe, lisebelisoa li omisoa ka metsi a 20%. |

| Ho penya & Aggregating | Mohaho oa Squeezer le agglomeratorinner: screw e le 'ngoe e kholo e kentsoeng ka har'a squeezer.ka screw rotating, thepa e tla ba push and compress.ka nako ena, metsi a tsoa sefeng.ka mor'a moo, ka mocheso o tsoang ho khohlano ea litšila, thepa e tla futhumatsoa hore e be semi-melting.ka mor'a moo, ka die / hlobo, mterial e tla hatelloa ka mocheso o phahameng.ka mor'a moo, lintho tse bonahalang li kena tsamaisong ea pelletizing, 'me li ntša sekhechana se thata.Mochine ona ha o sebelise matla a fokolang le ts'ebetso e ntle ea ho omisa, mongobo oa thepa e hlahisoang o ka laoloa pakeng tsa 5-10%. |

Lintlha tsa Khampani

| Bokhoni | 300-2000 lik'hilograma / hora |

| Kopo | filimi ea ho paka lijo, filimi ea temo, green house e sebelisang filimi e sebelisoang tšimong ea oli, mokotla oa PP, filimi ea PE, mokotla o lohiloeng, filimi ea LDPE shrink kapa filimi e boima e hatisitsoeng, mokotla oa samente, mokotla o mafura, mokotla o litšila. |

| Tlhaloso | Plastic Shredder/ Plastic Crusher, High Speed Friction Washer, Centrifugal Dewatering Washer, Spiral Feeder, Tanka e Phaphamang, Spiral Feeder , Li-Shafts tse peli tse Bolang, Squeezer kapa Squeezer & Agglomerator. E sebelisoa habonolo ka ho boloka matla |

| Mofuta oa Sephetho | Ho silakanya, ho hlatsoa, ho ntša metsi, ho omisa, ho kokobetsa le ho paka Mongobo oa ho qetela o ka ba ka hare ho 5% -10%.Lisebelisuoa li tla sebetsoa ka ho silakanya, ho hlatsuoa, ho ntša metsi, ho hatelloa le ho kopanya.Mongobo oa tlhahiso ea ho qetela o ka ba ka hare ho 2%. |

| Tšebeletso ea ka mor'a thekiso | Baenjiniere ba teng ka har'a ho kenya |

Hlokomela:

- Tanka e phaphametseng, e hlatsoang e ka fetoloa ho latela tlhoko ea moreki

- karolo ea mochini joalo ka shredder, crusher le eona e eketsa ho latela tlhoko ea moreki

- Saese ea mohala oa ho hlatsoa e ka ba nako e telele le e khuts'oane joalo ka ha lintho tse silafetseng tsa ts'ebetso joalo ka oli, lehlabathe, enke le tse ling

- Hona joale, li-wiring dryer kapa screw dryer lia fumaneha, sistimi e omisang le eona e latela botenya ba thepa ea ho sebetsa

- Ka kakaretso, ho fihlela li-microns tse 50, wiring e halikiloeng

- Melemo:

- Sehlopha sa meralo ea litsebi se nang le boiphihlelo ba lilemo tse 30

- Saese ea mohala oa ho hlatsoa e ka ba moralo joalo ka tlhoko ea bareki

- Ho sebetsa linthong tse fapaneng

- Bokhabane bo phahameng le ts'ebetso e phahameng

- Boloka litšenyehelo tsa hau tsa mosebetsi le tsa motlakase

- Matla a ho sebetsa a phahameng: 500-3500kg / hora

- PLC taolo e kopantsoeng le e arohaneng mochining o mong le o mong

- Phanele ea skrine ea ho ama, ts'ebetso e bonolo, ho beha leihlo le tlhokomelo

- Lisebelisoa tse tala tsa mochini: tšepe ea boleng bo holimo ea 304, e thata le e hanyetsanang le bere, ho etsa bonnete ba hore nako e telele e sebelisoa.

- Etsa bonnete ba hore ha ho na tšilafalo ea bobeli ho li-flakes

- Bokgoni bo bokgabane bo hlwekileng

Melemo ea Mochini oa ho Hlakola oa PURUI:

1.Plastiki ea ho itšeha filimi, ho hlatsoa, mochine oa ho tsosolosa o nang le lihlahisoa tse phahameng le bokhoni bo botle bo hloekileng

2.Mohala oohle oa polasetiki o sebelisetsoa ho sila, ho hlatsoa, ho ntša metsi le ho omisa filimi ea PP/PE, mokotla o lohiloeng oa PP.

3.Sebopeho se bonolo, ts'ebetso e bonolo, bokhoni bo boholo, ho boloka matla, polokeho

4.Ho laola ka tsela e iketsang, sebopeho se kopaneng, bokhoni bo botle ba tlhahiso, bokhoni bo hloekileng bo phethahetsengRe se re itokiselitse ho arolelana tsebo ea rona ea papatso lefatšeng ka bophara mme re u khothaletsa thepa e loketseng ka litheko tse ngata tse mabifi tsa ho rekisa.Kahoo Profi Tools e u tlisetsa theko e ntle ka ho fetisisa ea chelete 'me re ikemiselitse ho hlahisa hammoho le Massive Selection bakeng sa Mochini oa ho Hlatsoa Letlapa la China o Hlatsoang le ho Hlōla, Re na le ts'epo ea hore re ka fana ka lihlahisoa tsa boleng bo holimo ka theko e tlase, ts'ebeletso e ntle ka mor'a thekiso. ho bareki.'Me re tla theha bokamoso bo khanyang.

Khetho e kholo bakeng saChina Plastic Granulator, Mochini oa Granulating oa Filimi ea litšila, Khamphani ea rona e thehile likamano tse tsitsitseng tsa khoebo le lik'hamphani tse ngata tse tsebahalang tsa malapeng hammoho le bareki ba mose ho maoatle.Ka sepheo sa ho fana ka lintho tsa boleng bo holimo ho bareki ba li-cots tse tlase, re ikemiselitse ho ntlafatsa bokhoni ba eona ho lipatlisiso, nts'etsopele, tlhahiso le tsamaiso.Re motlotlo ho fumana kananelo ho tsoa ho bareki ba rona.Ho fihlela joale re fetile ISO9001 ka 2005 le ISO/TS16949 ka 2008. Likhoebo tsa "boleng ba ho phela, botšepehi ba tsoelo-pele" ka morero, li amohela ka tieo bo-rakhoebo ba malapeng le ba tsoang linaheng tse ling ho etela ho buisana ka tšebelisano.

Mochini oa polasetiki o recycleng le oa granulating ke mofuta oa lisebelisoa tse sebelisoang ho khutlisetsa litšila tsa polasetiki ho li-granules kapa li-pellets tse ka sebelisoang hape ho etsa lihlahisoa tse ncha tsa polasetiki.Hangata mochini o sebetsa ka ho petsola kapa ho sila litšila tsa polasetiki hore li be likotoana tse nyane, ebe oa qhibiliha ebe oa li ntša ka lefi ho etsa li-pellets kapa granules.

Ho na le mefuta e fapaneng ea metjhini e nchafatsang ea polasetiki le ea granulating e fumanehang, ho kenyeletsoa screw le li-twin-screw extruder.Mechini e meng e boetse e kenyelletsa likarolo tse ling tse kang li-skrini ho tlosa litšila ho litšila tsa polasetiki kapa mekhoa ea ho pholisa ho netefatsa hore li-pellets li tiisitsoe hantle.Mochini oa ho hlatsoa botlolo ea PET, PP e lohiloeng ka mekotla ea ho hlatsoa mohala

Mechini e nchafatsang polasetiki le ea granulating hangata e sebelisoa liindastering tse hlahisang litšila tse ngata tsa polasetiki, joalo ka ho paka, likoloi le kaho.Ka ho tsosolosa litšila tsa polasetiki, mechine ena e thusa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha polasetiki le ho boloka lisebelisoa ka ho sebelisa thepa e neng e tla lahloa.

Thepa ea li-betri tsa lithium ke mofuta oa lisebelisoa tse sebelisetsoang ho khutlisa le ho khutlisa lisebelisoa tsa bohlokoa ho tsoa libetering tsa lithium-ion, tse sebelisoang hangata lisebelisoa tsa elektroniki tse kang li-smartphone, lilaptop le likoloi tsa motlakase.Thepa hangata e sebetsa ka ho pshatla libeteri likarolong tsa tsona, joalo ka lisebelisoa tsa cathode le anode, tharollo ea electrolyte le lithapo tsa tšepe, ebe li arola le ho hloekisa lisebelisoa tsena hore li sebelisoe hape.

Ho na le mefuta e fapaneng ea lisebelisoa tsa ho nchafatsa betri ea lithium tse fumanehang, ho kenyelletsa lits'ebetso tsa pyrometallurgical, lits'ebetso tsa hydrometallurgical, le lits'ebetso tsa mochini.Ts'ebetso ea pyrometallurgical e kenyelletsa ts'ebetso e phahameng ea mocheso oa libeteri ho khutlisa litšepe tse kang koporo, nickel le cobalt.Ts'ebetso ea Hydrometallurgical e sebelisa tharollo ea lik'hemik'hale ho qhala likarolo tsa betri le ho khutlisa litšepe, ha lits'ebetso tsa mochini li kenyelletsa ho pshatla le ho sila libeteri ho arola lisebelisoa.

Thepa ea ho sebelisa betri ea lithium e bohlokoa bakeng sa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha betri le ho baballa lisebelisoa ka ho khutlisa litšepe tsa bohlokoa le lisebelisoa tse ka sebelisoang hape ka libeteri tse ncha kapa lihlahisoa tse ling.

Ntle le melemo ea ho boloka tikoloho le lisebelisoa, lisebelisoa tsa ho sebelisa betri ea lithium le tsona li na le melemo ea moruo.Ho fumana litšepe tsa bohlokoa le lisebelisoa ho tsoa libetering tse sebelisitsoeng ho ka fokotsa litšenyehelo tsa ho hlahisa libeteri tse ncha, hammoho le ho theha mekhoa e mecha ea chelete bakeng sa lik'hamphani tse amehang ts'ebetsong ea ho e sebelisa hape.

Ho feta moo, tlhokahalo e ntseng e eketseha ea likoloi tsa motlakase le lisebelisoa tse ling tsa elektroniki e tsamaisa tlhokahalo ea indasteri e sebetsang hantle le e tsitsitseng ea ho sebelisa li-betri.Thepa ea ho sebelisa betri ea lithium e ka thusa ho fihlela tlhoko ena ka ho fana ka mokhoa o tšepahalang le o theko e tlase oa ho khutlisa lisebelisoa tsa bohlokoa libetering tse sebelisitsoeng.

Leha ho le joalo, ho bohlokoa ho hlokomela hore ho sebelisa betri ea lithium e ntse e le indasteri e ncha, 'me ho na le liphephetso tse lokelang ho hlōloa mabapi le ho theha mekhoa e sebetsang hantle le e bolokang chelete e ngata.Ho feta moo, ts'ebetso e nepahetseng le ho lahla litšila tsa betri ho bohlokoa ho qoba likotsi tsa tikoloho le bophelo bo botle.Ka hona, melaoana e nepahetseng le mehato ea polokeho e tlameha ho ba teng ho netefatsa ts'ebetso e nang le boikarabelo le ho tsosolosoa ha libeteri tsa lithium.