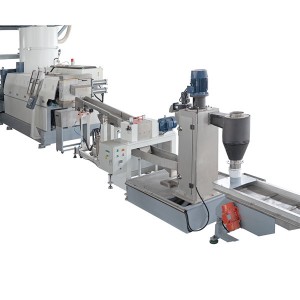

Mochini oa pelletizing oa mofuta oa SJ bakeng sa lipolasetiki tse thata tsa PP PE le li-plastiki tse petelitsoeng

Video:

Lintlha tse akaretsang:

SJ pelletizing machine ke haholo-holo bakeng sa ho tsosolosa li-plastiki tse thata, tse kang PE, PP, PS, ABS, PC, PA6 joalo-joalo. le libotlolo tsa li-shampoo, joalo-joalo. E ka boela ea sebelisoa hape ho sebelisoa lifilimi tse omeletseng tsa PE, PP le li-plastiki tse bonolo tse hlatsoitsoeng.

Kopo:

l E pshatlehile kapa e sila hape PE, PP, PS, ABS, PC, PA6

l Lifilimi tse hlatsoitsoeng tsa PP le PE.

Likaroloana:

1.Ho hloekisa ka makhetlo a mabeli ho tla tiisa boleng ba li-pellets.Boemo ba letlooeng la ho sefa mohato oa pele o ka sebelisa 60mesh.Mokhahlelo oa bobeli oa ho sefa letlooeng e tla ba 80-100mesh.

2.Great vacuum degassing system.Re sebelisa pompo ea vacuum ea ho nosetsa moleng oa pelletizing.Khase e khathetseng e tsoang ho extruder ebe e kena ka har'a silindara ea metsi bakeng sa ho sefa.

3.Moqapi oa screw o khethehile ho lisebelisoa tse khethehileng.

4.Li-heaters tseo re li sebelisitseng ka barrel li molemo ka ho fetisisa ebile li ka tšeptjoa Chaena ka nako e telele ea tšebeletso.

5.Mokhoa oa Pelletizing ke oa boikhethelo.Pelletizing ea nosetsang e loketse lifilimi tsa PP le PE, athe bakeng sa strand pelletizing e ka sebelisoa ho PP PE le PC le ABS le PA.Hape pelletizing ka tlas'a metsi e tla ba bokahohle.Mekhoa eohle ea pelletizing e tla ba bonolo ho e boloka le nako e telele ea tšebeletso.

6. Mefuta e metle ea likoloi le lebokose la li-gearbox tse phahameng tse tšoanelehang.Re sebelisa li-motor tsa China tse ntle ka ho fetisisa, Dazhong, le WEG tse nang le setifikeiti sa UL, li-motor tsa ABB, le li-motors tsa Siemens ka boikhethelo.Likarolo tsa motlakase li sebelisa mofuta oa machaba oa Schneider kapa Siemens.Taolo ea mocheso OMRON.Siemens PLC taolo ea fumaneha.Mokhoa o motle oa ts'ireletso ea motlakase mochining.

7.Moqapi o motle bakeng sa polokeho le ts'ebeliso ea semela.Re na le taolo e tiileng ea boleng.

Re bile tšimong ena ea polasetiki ea pelletiizng ka lilemo tse fetang 16 re romella linaheng tse fetang 80 lefatšeng ka bophara.Ka boiphihlelo bo bongata le basebetsi ba theknoloji ho rarolla bothata ba haumochine oa polasetiki oa ho tsosolosa.

Mochini oa polasetiki o recycleng le oa granulating ke mofuta oa lisebelisoa tse sebelisoang ho khutlisetsa litšila tsa polasetiki ho li-granules kapa li-pellets tse ka sebelisoang hape ho etsa lihlahisoa tse ncha tsa polasetiki.Hangata mochini o sebetsa ka ho petsola kapa ho sila litšila tsa polasetiki hore li be likotoana tse nyane, ebe oa qhibiliha ebe oa li ntša ka lefi ho etsa li-pellets kapa granules.

Ho na le mefuta e fapaneng ea metjhini e nchafatsang ea polasetiki le ea granulating e fumanehang, ho kenyeletsoa screw le li-twin-screw extruder.Mechini e meng e boetse e kenyelletsa likarolo tse ling tse kang li-skrini ho tlosa litšila ho litšila tsa polasetiki kapa mekhoa ea ho pholisa ho netefatsa hore li-pellets li tiisitsoe hantle.Mochini oa ho hlatsoa botlolo ea PET, PP e lohiloeng ka mekotla ea ho hlatsoa mohala

Mechini e nchafatsang polasetiki le ea granulating hangata e sebelisoa liindastering tse hlahisang litšila tse ngata tsa polasetiki, joalo ka ho paka, likoloi le kaho.Ka ho tsosolosa litšila tsa polasetiki, mechine ena e thusa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha polasetiki le ho boloka lisebelisoa ka ho sebelisa thepa e neng e tla lahloa.

Thepa ea li-betri tsa lithium ke mofuta oa lisebelisoa tse sebelisetsoang ho khutlisa le ho khutlisa lisebelisoa tsa bohlokoa ho tsoa libetering tsa lithium-ion, tse sebelisoang hangata lisebelisoa tsa elektroniki tse kang li-smartphone, lilaptop le likoloi tsa motlakase.Thepa hangata e sebetsa ka ho pshatla libeteri likarolong tsa tsona, joalo ka lisebelisoa tsa cathode le anode, tharollo ea electrolyte, le lithapo tsa tšepe, ebe li arola le ho hloekisa lisebelisoa tsena hore li sebelisoe hape.

Ho na le mefuta e fapaneng ea lisebelisoa tsa ho nchafatsa betri ea lithium tse fumanehang, ho kenyelletsa lits'ebetso tsa pyrometallurgical, lits'ebetso tsa hydrometallurgical, le lits'ebetso tsa mochini.Ts'ebetso ea pyrometallurgical e kenyelletsa ts'ebetso ea mocheso o phahameng oa libeteri ho khutlisa litšepe tse kang koporo, nickel le cobalt.Ts'ebetso ea Hydrometallurgical e sebelisa tharollo ea lik'hemik'hale ho qhala likarolo tsa betri le ho khutlisa litšepe, ha lits'ebetso tsa mochini li kenyelletsa ho pshatla le ho sila libeteri ho arola lisebelisoa.

Thepa ea ho sebelisa betri ea lithium e bohlokoa bakeng sa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha betri le ho baballa lisebelisoa ka ho khutlisa litšepe tsa bohlokoa le lisebelisoa tse ka sebelisoang hape ka libeteri tse ncha kapa lihlahisoa tse ling.

Ntle le melemo ea ho boloka tikoloho le lisebelisoa, lisebelisoa tsa ho sebelisa betri ea lithium le tsona li na le melemo ea moruo.Ho fumana litšepe tsa bohlokoa le lisebelisoa ho tsoa libetering tse sebelisitsoeng ho ka fokotsa litšenyehelo tsa ho hlahisa libeteri tse ncha, hammoho le ho theha mekhoa e mecha ea chelete bakeng sa lik'hamphani tse amehang ts'ebetsong ea ho e sebelisa hape.

Ho feta moo, tlhokahalo e ntseng e eketseha ea likoloi tsa motlakase le lisebelisoa tse ling tsa elektroniki e tsamaisa tlhokahalo ea indasteri e sebetsang hantle le e tsitsitseng ea ho sebelisa li-betri.Thepa ea ho sebelisa betri ea lithium e ka thusa ho fihlela tlhoko ena ka ho fana ka mokhoa o tšepahalang le o theko e tlase oa ho khutlisa lisebelisoa tsa bohlokoa libetering tse sebelisitsoeng.

Leha ho le joalo, ho bohlokoa ho hlokomela hore ho sebelisa betri ea lithium e ntse e le indasteri e ncha, 'me ho na le liphephetso tse lokelang ho hlōloa mabapi le ho theha mekhoa e sebetsang hantle le e bolokang chelete e ngata.Ho feta moo, ts'ebetso e nepahetseng le ho lahla litšila tsa betri ho bohlokoa ho qoba likotsi tsa tikoloho le bophelo bo botle.Ka hona, melaoana e nepahetseng le mehato ea polokeho e tlameha ho ba teng ho netefatsa ts'ebetso e nang le boikarabelo le ho tsosolosoa ha libeteri tsa lithium.