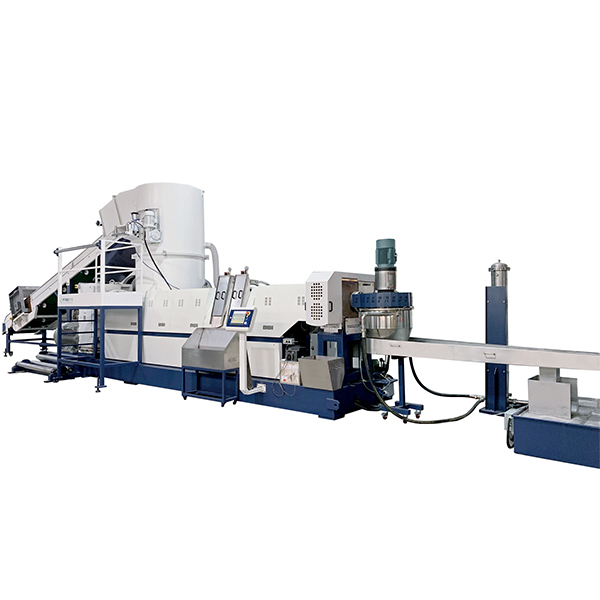

Mochini oa granulation oa mochini oa BOPP oa filimi

Mochini oa granulating oa filimi oa BOPP o kopanya mesebetsi ea ho silakanya, ho kopanya, ho etsa polasetiki le granulation, 'me e loketse ts'ebetso ea polasetiki le lits'ebetso tsa granulation.Granulator ea filimi ea BOPP ke tharollo e ka tšeptjoang le e sebetsang bakeng sa ho regranulation le pelletizing ea filimi ea polasetiki, raffia fiber, filament, mokotla, mokotla o lohiloeng le thepa ea foam.Sehlahisoa sa ho qetela se hlahisoang ke filimi ea Fangsheng BOPP granulator / pelletizer ke ka mokhoa oa li-granules / granules, tse ka kenngoa ka ho toba mocheng oa tlhahiso bakeng sa ho phatloha ha filimi, extrusion ea pipe le ente ea polasetiki, joalo-joalo.

Mochini ke mofuta oa mochini oa polasetiki o recycleng.E ka fetisetsa matrial a litšila ka har'a li-pellets tse molemo bakeng sa tlhahiso e tsoelang pele.

Likarolo tsa mochini oa BOPP Filimi ea Granulating:

1. Mochine oa granulating oa filimi oa BOPP o na le mokhoa o motle oa ho ikamahanya le maemo, hoo e batlang e le mefuta eohle ea granulation e tloaelehileng ea polasetiki e ka fetoloa.Karo-karolelano ea tšebeliso ea matla ea mochine oa polasetiki oa recyling e tlase.Boleng ba sehlahisoa sa sehlahisoa le phaello e pharaletseng ea tlhōlisano e totobetse.

2. Qetellong ea "screw barrel", "recycling granulator" e nang le mochini o fetolang skrineng sa "hydraulic non-stop" e nang le mekholo e 'meli e ka sefang litšila ka har'a polasetiki e qhibilihang.

3. Likaroloana tse ncha ka mor'a ho bopa kapa ho kenngoa li ka sebelisoa ho etsa lihlahisoa tse ncha tsa polasetiki.Ka mohlala, lifilimi tsa polasetiki, mekotla ea polasetiki, libotlolo tsa polasetiki, liphalete tsa polasetiki, mabokose a polasetiki, libarele tsa polasetiki, joalo-joalo.

4. Mokhoa oa ho tsamaisa motlakase o itekanetseng o amoheloa ho netefatsa hore ho sebetsa ho tloaelehileng ha motlakase.

Lifilimi tsa BOPP Tse Hlahisang Mochini oa Teknoloji Parameter ea Granulating:

Tloaelehileng:

| Mohlala | ML85 | ML100 | ML130 | ML160 | ML180 |

| Sephetho(kg/h) | 120-180 | 180-300 | 400-500 | 600-800 | 800-1000 |

Tlhahiso e phahameng, tshebediso e tlase:

| Mohlala | ML100B | ML130B | ML160B | ML180B |

| Sephetho(kg/h) | 350-400 | 500-600 | 600-800 | 1000-1100 |

Lifilimi tsa BOPP Mokhoa oa ho Sebelisa Mochini oa Granulating:

filimi ea bopp → conveyor lebanta→ compactor→ screw extruder → hydraulic screen changer → pelletizing system → phetiso ea moea → polokelo ea silo

Lintlha tsa Thepa ea Filimi ea BOPP ea Granulating:

Metsi-ring ea ho itšeha ka mokhoa oa ho itšeha

Mekhoa ea ho itšeha ea metsi-ring-ring e atisa ho sebelisoa.Ka mokhoa oa ho itšeha ka metsi-ring-face-face, li-blades tsa rotary li tla lumellana ka ho feletseng le haufi le sebaka sa sefahleho sa die-face ho netefatsa hore seha se sebetsa hantle.Lebelo la rotary la li-blades le fetoha ka tsela e iketsang ke sistimi ea module ho latela khatello ea ho qhibiliha sefahlehong sa lefu.

video:

Leha e le efe potso, ka kopo ikopanye le rona ka bolokolohi.

Mochini oa polasetiki o recycleng le oa granulating ke mofuta oa lisebelisoa tse sebelisoang ho khutlisetsa litšila tsa polasetiki ho li-granules kapa li-pellets tse ka sebelisoang hape ho etsa lihlahisoa tse ncha tsa polasetiki.Hangata mochini o sebetsa ka ho petsola kapa ho sila litšila tsa polasetiki hore li be likotoana tse nyane, ebe oa qhibiliha ebe oa li ntša ka lefi ho etsa li-pellets kapa granules.

Ho na le mefuta e fapaneng ea metjhini e nchafatsang ea polasetiki le ea granulating e fumanehang, ho kenyeletsoa screw le li-twin-screw extruder.Mechini e meng e boetse e kenyelletsa likarolo tse ling tse kang li-skrini ho tlosa litšila ho litšila tsa polasetiki kapa mekhoa ea ho pholisa ho netefatsa hore li-pellets li tiisitsoe hantle.Mochini oa ho hlatsoa botlolo ea PET, PP e lohiloeng ka mekotla ea ho hlatsoa mohala

Mechini e nchafatsang polasetiki le ea granulating hangata e sebelisoa liindastering tse hlahisang litšila tse ngata tsa polasetiki, joalo ka ho paka, likoloi le kaho.Ka ho tsosolosa litšila tsa polasetiki, mechine ena e thusa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha polasetiki le ho boloka lisebelisoa ka ho sebelisa thepa e neng e tla lahloa.

Thepa ea li-betri tsa lithium ke mofuta oa lisebelisoa tse sebelisetsoang ho khutlisa le ho khutlisa lisebelisoa tsa bohlokoa ho tsoa libetering tsa lithium-ion, tse sebelisoang hangata lisebelisoa tsa elektroniki tse kang li-smartphone, lilaptop le likoloi tsa motlakase.Thepa hangata e sebetsa ka ho pshatla libeteri likarolong tsa tsona, joalo ka lisebelisoa tsa cathode le anode, tharollo ea electrolyte, le lithapo tsa tšepe, ebe li arola le ho hloekisa lisebelisoa tsena hore li sebelisoe hape.

Ho na le mefuta e fapaneng ea lisebelisoa tsa ho nchafatsa betri ea lithium tse fumanehang, ho kenyelletsa lits'ebetso tsa pyrometallurgical, lits'ebetso tsa hydrometallurgical, le lits'ebetso tsa mochini.Ts'ebetso ea pyrometallurgical e kenyelletsa ts'ebetso ea mocheso o phahameng oa libeteri ho khutlisa litšepe tse kang koporo, nickel le cobalt.Ts'ebetso ea Hydrometallurgical e sebelisa tharollo ea lik'hemik'hale ho qhala likarolo tsa betri le ho khutlisa litšepe, ha lits'ebetso tsa mochini li kenyelletsa ho pshatla le ho sila libeteri ho arola lisebelisoa.

Thepa ea ho sebelisa betri ea lithium e bohlokoa bakeng sa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha betri le ho baballa lisebelisoa ka ho khutlisa litšepe tsa bohlokoa le lisebelisoa tse ka sebelisoang hape ka libeteri tse ncha kapa lihlahisoa tse ling.

Ntle le melemo ea ho boloka tikoloho le lisebelisoa, lisebelisoa tsa ho sebelisa betri ea lithium le tsona li na le melemo ea moruo.Ho fumana litšepe tsa bohlokoa le lisebelisoa ho tsoa libetering tse sebelisitsoeng ho ka fokotsa litšenyehelo tsa ho hlahisa libeteri tse ncha, hammoho le ho theha mekhoa e mecha ea chelete bakeng sa lik'hamphani tse amehang ts'ebetsong ea ho e sebelisa hape.

Ho feta moo, tlhokahalo e ntseng e eketseha ea likoloi tsa motlakase le lisebelisoa tse ling tsa elektroniki e tsamaisa tlhokahalo ea indasteri e sebetsang hantle le e tsitsitseng ea ho sebelisa li-betri.Thepa ea ho sebelisa betri ea lithium e ka thusa ho fihlela tlhoko ena ka ho fana ka mokhoa o tšepahalang le o theko e tlase oa ho khutlisa lisebelisoa tsa bohlokoa libetering tse sebelisitsoeng.

Leha ho le joalo, ho bohlokoa ho hlokomela hore ho sebelisa betri ea lithium e ntse e le indasteri e ncha, 'me ho na le liphephetso tse lokelang ho hlōloa mabapi le ho theha mekhoa e sebetsang hantle le e bolokang chelete e ngata.Ho feta moo, ts'ebetso e nepahetseng le ho lahla litšila tsa betri ho bohlokoa ho qoba likotsi tsa tikoloho le bophelo bo botle.Ka hona, melaoana e nepahetseng le mehato ea polokeho e tlameha ho ba teng ho netefatsa ts'ebetso e nang le boikarabelo le ho tsosolosoa ha libeteri tsa lithium.