-

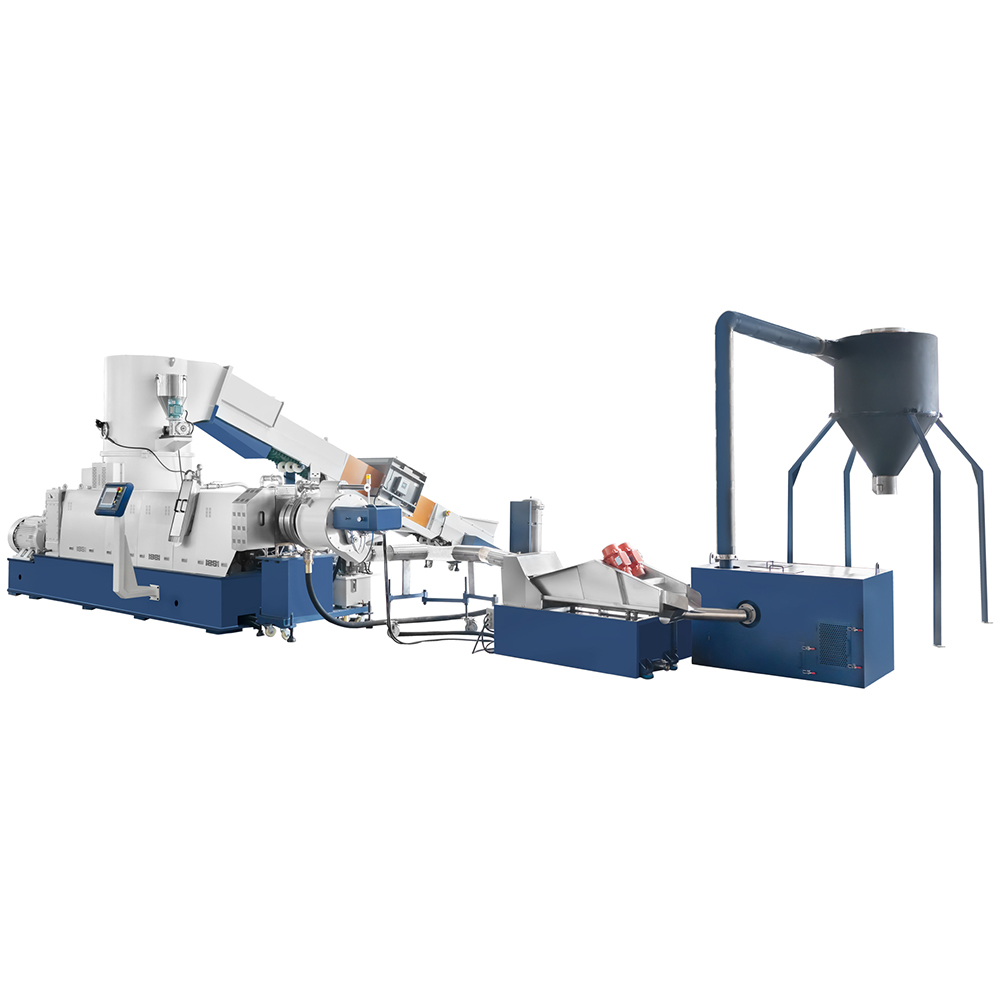

PP PE Film Recycling Extruder Machine e nang le Shredding Agglomerator

Ka tšepe e nyane e robeha screw le barrel habonolo, bareki ba bangata ba kopa

Lebanta conveyor fumana inter-lock le shredding compactor.Hang ha mocheso o ka hare oa compactor o phahame haholo, 'me ampere ea eona e eketseha haholo, conveyor ea lebanta e emisa ka bo eona.

Compactor cutter valve, e ka lekola lebelo la phepelo ea lintho tse bonahalang ka ho qoba compactor e qhibilihisitsoeng.Moralo ona o thusa haholo bakeng sa ho seha ho leka-lekana.

Sistimi e habeli ea vacuum degassing e ka qetang khase le metsi ka bongata bo boholo.

Sistimi e fapaneng ea hydraulic filtering e netefatsa skrine e kholo ea ho sefa bakeng sa litšila.Khatello e tsitsitseng le lebelo la ho fetola skrine ka potlako.

Sisteme ea ho itšeha e sebelisoang ho latela sebopeho sa lintho tse bonahalang -

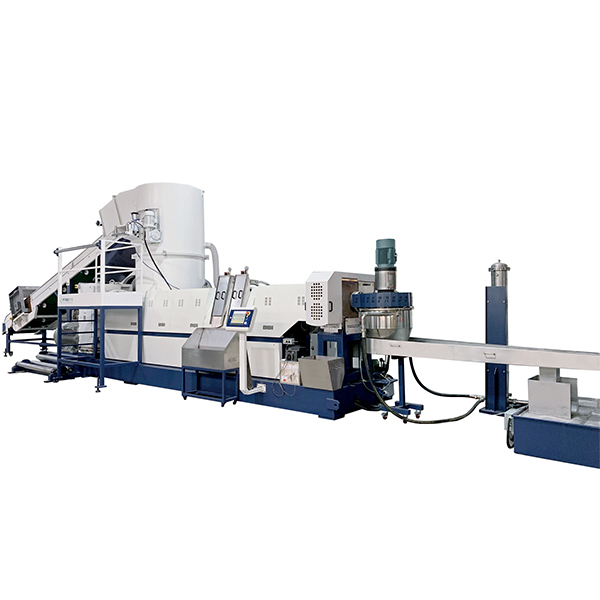

ML Model Single Screw Plastic Recycling Extruder with Cutter Compactor

Ka tšepe e nyane e robeha screw le barrel habonolo, bareki ba bangata ba kopa

Lebanta conveyor fumana inter-lock le shredding compactor.Hang ha mocheso o ka hare oa compactor o phahame haholo, 'me ampere ea eona e eketseha haholo, conveyor ea lebanta e emisa ka bo eona.

Compactor cutter valve, e ka lekola lebelo la phepelo ea lintho tse bonahalang ka ho qoba compactor e qhibilihisitsoeng.Moralo ona o thusa haholo bakeng sa ho seha ho leka-lekana.

Sistimi e habeli ea vacuum degassing e ka qetang khase le metsi ka bongata bo boholo.

Sistimi e fapaneng ea hydraulic filtering e netefatsa skrine e kholo ea ho sefa bakeng sa litšila.Khatello e tsitsitseng le lebelo la ho fetola skrine ka potlako.

Sisteme ea ho itšeha e sebelisoang ho latela sebopeho sa lintho tse bonahalang -

Mochini oa granulation oa mochini oa BOPP oa filimi

Mochini oa granulation oa filimi oa BOPP o etselitsoe ho khutlisa lifilimi tsa poso tsa BOPP le likhechana tsa maqephe.

-

Masela a PET a faeba a pelletizing le mochini o recycleng

E ka sebelisa boholo ba lipolasetiki tse bonolo le tse ling tse thata.Lintho tse bonolo li na le li-wholes rolls le crusho roala likhoele le lifilimi tsa PET, masela a PET,LLDPE, LDPE,HDPE,PP,BOPP,CPP ho tsoa indastering ea poso kapa ea poso.

-

Mochini o arolang betri ea lithium-ion

Mochini o arolang betri ea lithium-ion

Ka mantsoe a bonolo, lera ke filimi ea polasetiki e nang le porous e entsoeng ka lisebelisoa tsa motheo tse kang PP le PE le li-additives.Karolo ea eona e ka sehloohong ho libeteri tsa lithium-ion ke ho boloka ho kenya letsoho pakeng tsa li-electrode tse ntle le tse mpe ha li-ion tsa lithium shuttle pakeng tsa tsona ho thibela li-circuits tse khutšoane.Ka hona, index ea bohlokoa ea ts'ebetso ea filimi ke ho hanyetsa mocheso, e hlahisoang ke ntlha ea eona ea ho qhibiliha.Hona joale, bahlahisi ba bangata ba lifilimi lefatšeng ba sebelisa mokhoa oa metsi, ke hore, filimi e otlolloa ka solvent le plasticizer, ebe li-pores li thehoa ke mouoane oa solvent.Sebaka se phahameng ka ho fetisisa sa ho qhibiliha ha mochine oa motlakase oa PE lithium-ion betri separator e qalileng ke Tonen Chemical ea Japane ke 170 ° C. Re ka boela ra fana ka mochine oa pelletizing oa ho arola betri.Searohanyi sa betri haholo-holo se entsoe ka mokhoa o metsi.