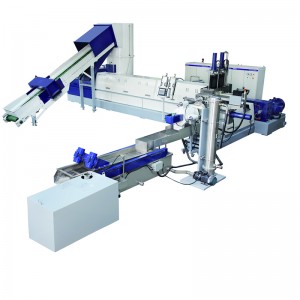

Mochini oa ho Recycling oa polasetiki bakeng sa filimi ea HDPE ea litšila (filimi ea karohano ea betri ea lithium)

Mochini oa Recycling oa polasetiki bakeng sa filimi ea HDPE ea litšila(filimi e arolang betri ea lithium)

Ts'ebetsong ea tlhahiso ea lithium betri separator ka hydrometallurgy, ho tla hlahisoa lisebelisoa tse ngata tsa offcut (HDPE ultra-high molecular weight polyethylene).Li-offcut tsena (filimi ea litšila ea HDPE) li ka sebelisoa hape bakeng sa liphaephe, lipolasetiki tse fetotsoeng le lihlahisoa tse ling, ka boleng bo phahameng ba tšebeliso.Nakong ea ts'ebetso ea lihlahisoa tsena, lisebelisoa tsa offcut li tla kenngoa granulated pele li sebelisoa.Ka lebaka la sekhahla se tlase sa ho qhibiliha ha UHMWPE kapa UHMWPE, ho sebetsa ha extrusion ho thata.PURUI e fana ka mokhoa o mocha oa ho senyeha le ho hlaphoheloa ha litšila tsa polyethylene tse phahameng haholo kapa tse phahameng haholo.Mokhoa ona o na le mokhoa o bonolo oa ho hlaphoheloa, o ka sebelisetsoang ho nyenyefatsa le ho khutlisa polyethylene ea boima ba limolek'hule e phahameng haholo kapa e phahameng ka ho fetisisa ka mokhoa o se nang botsoalle le o sebetsang hantle, ho etsa hore litšila tsa polyethylene ka mor'a ho senyeha ho be le ts'ebetso e ntle, kahoo ho hlokomela ho tsosolosoa ha offcut. thepa, ka melemo e metle ea moruo.

Plastic recycling lineke ho pshatla ketane ea molek'hule ea polyethylene e phahameng haholo kapa e phahameng haholo ea boima ba molek'hule (UHMWPE) ka ho pshatla filimi (ke hore, lintho tse setseng tse nang le polyethylene e phahameng haholo kapa e phahameng haholo) ebe e e fepa ho extruder, le ebe o qhibiliha extruding tlas'a mocheso o itseng o phahameng le ketso ea ho kuta ea screw extruder, e le hore ketane ea molek'hule ea UHMWPE kapa polyethylene e phahameng ea molek'hule e ka robeha, kahoo ho ba le mocheso o phahameng oa ho kuta le ho sebetsa habonolo, ho lemoha ho hlaphoheloa ha lisebelisoa le ho sebelisoa hape. , le ho boloka litšenyehelo tsa khoebo.

Mehato ea ho tsosolosa polasetiki:

(1) Silakanya: ho pshatla filimi ea litšila ea HDPE joalo ka 30mm ka mochini o silafatsang oa polasetiki ebe o fepa ka har'a agglomerator ka lebanta conveyor.

(2) Extrusion: extruding tlas'a mocheso pakeng tsa 160 ho 250 ℃, lebelo la rotary e le 60-150rpm, L/D e le 30-50

(3) Granulation / pelletizing: lisebelisoa tse qhibilihisang le tse tsoang li khaotsoe ke tsamaiso ea ho itšeha ka tlas'a metsi, li-pellets tsa ho qetela e le 2mm.

(4) Dryer le pokello: ka mor'a ho omisa le ho bokella ka silo, li-pellets tsa ho qetela li qhibiliha ka 0.83-1.31g / 10min.

Video:

Likaroloana:

Mokhoa o bonolo, theko e tlase

Setšoantšo sa PURUImola oa granulatione ka hlokomela ho tsosolosoa ha lisebelisoa tsa litšila tsa polyethylene e phahameng haholo kapa e phahameng ka ho fetisisa ea limolek'hule, ke hore, offcut, 'me ka ho toba e sebelisetsoe ho sebetsa liphaephe tse tlaase, li-plastiki tse fetotsoeng le lihlahisoa tse ling, ho rarolla bothata ba ho sebetsana le mathata ka mekhoa ea setso;Ho phaella moo, ha ho na karolo ea lik'hemik'hale e kenyelletsoeng nakong ea ts'ebetso ea ho tsosolosa / ea granulating, e ke keng ea baka tšilafalo ea bobeli 'me e tla ba botsoalle haholoanyane tikolohong;Ho finyelloa ho tsosolosoa ha mehloli ea litšila, ho boloka litšenyehelo 'me ho na le melemo e meholo ea moruo.

Thepa ea granulation le mokhoa oa ho hlaphoheloa o entsoeng ke PURUI ka katleho e nyenyefatsa le ho khutlisa UHMWPE.Thepa e ka qhibiliha mme ea phalla, 'me e ka khutlisoa hape.Boitsebiso bo na le matla a phahameng a mochine.

Mochini oa polasetiki o recycleng le oa granulating ke mofuta oa lisebelisoa tse sebelisoang ho khutlisetsa litšila tsa polasetiki ho li-granules kapa li-pellets tse ka sebelisoang hape ho etsa lihlahisoa tse ncha tsa polasetiki.Hangata mochini o sebetsa ka ho petsola kapa ho sila litšila tsa polasetiki hore li be likotoana tse nyane, ebe oa qhibiliha ebe oa li ntša ka lefi ho etsa li-pellets kapa granules.

Ho na le mefuta e fapaneng ea metjhini e nchafatsang ea polasetiki le ea granulating e fumanehang, ho kenyeletsoa screw le li-twin-screw extruder.Mechini e meng e boetse e kenyelletsa likarolo tse ling tse kang li-skrini ho tlosa litšila ho litšila tsa polasetiki kapa mekhoa ea ho pholisa ho netefatsa hore li-pellets li tiisitsoe hantle.Mochini oa ho hlatsoa botlolo ea PET, PP e lohiloeng ka mekotla ea ho hlatsoa mohala

Mechini e nchafatsang polasetiki le ea granulating hangata e sebelisoa liindastering tse hlahisang litšila tse ngata tsa polasetiki, joalo ka ho paka, likoloi le kaho.Ka ho tsosolosa litšila tsa polasetiki, mechine ena e thusa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha polasetiki le ho boloka lisebelisoa ka ho sebelisa thepa e neng e tla lahloa.

Thepa ea li-betri tsa lithium ke mofuta oa lisebelisoa tse sebelisetsoang ho khutlisa le ho khutlisa lisebelisoa tsa bohlokoa ho tsoa libetering tsa lithium-ion, tse sebelisoang hangata lisebelisoa tsa elektroniki tse kang li-smartphone, lilaptop le likoloi tsa motlakase.Thepa hangata e sebetsa ka ho pshatla libeteri likarolong tsa tsona, joalo ka lisebelisoa tsa cathode le anode, tharollo ea electrolyte le lithapo tsa tšepe, ebe li arola le ho hloekisa lisebelisoa tsena hore li sebelisoe hape.

Ho na le mefuta e fapaneng ea lisebelisoa tsa ho nchafatsa betri ea lithium tse fumanehang, ho kenyelletsa lits'ebetso tsa pyrometallurgical, lits'ebetso tsa hydrometallurgical, le lits'ebetso tsa mochini.Ts'ebetso ea pyrometallurgical e kenyelletsa ts'ebetso e phahameng ea mocheso oa libeteri ho khutlisa litšepe tse kang koporo, nickel le cobalt.Ts'ebetso ea Hydrometallurgical e sebelisa tharollo ea lik'hemik'hale ho qhala likarolo tsa betri le ho khutlisa litšepe, ha lits'ebetso tsa mochini li kenyelletsa ho pshatla le ho sila libeteri ho arola lisebelisoa.

Thepa ea ho sebelisa betri ea lithium e bohlokoa bakeng sa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha betri le ho baballa lisebelisoa ka ho khutlisa litšepe tsa bohlokoa le lisebelisoa tse ka sebelisoang hape ka libeteri tse ncha kapa lihlahisoa tse ling.

Ntle le melemo ea ho boloka tikoloho le lisebelisoa, lisebelisoa tsa ho sebelisa betri ea lithium le tsona li na le melemo ea moruo.Ho fumana litšepe tsa bohlokoa le lisebelisoa ho tsoa libetering tse sebelisitsoeng ho ka fokotsa litšenyehelo tsa ho hlahisa libeteri tse ncha, hammoho le ho theha mekhoa e mecha ea chelete bakeng sa lik'hamphani tse amehang ts'ebetsong ea ho e sebelisa hape.

Ho feta moo, tlhokahalo e ntseng e eketseha ea likoloi tsa motlakase le lisebelisoa tse ling tsa elektroniki e tsamaisa tlhokahalo ea indasteri e sebetsang hantle le e tsitsitseng ea ho sebelisa li-betri.Thepa ea ho sebelisa betri ea lithium e ka thusa ho fihlela tlhoko ena ka ho fana ka mokhoa o tšepahalang le o theko e tlase oa ho khutlisa lisebelisoa tsa bohlokoa libetering tse sebelisitsoeng.

Leha ho le joalo, ho bohlokoa ho hlokomela hore ho sebelisa betri ea lithium e ntse e le indasteri e ncha, 'me ho na le liphephetso tse lokelang ho hlōloa mabapi le ho theha mekhoa e sebetsang hantle le e bolokang chelete e ngata.Ho feta moo, ts'ebetso e nepahetseng le ho lahla litšila tsa betri ho bohlokoa ho qoba likotsi tsa tikoloho le bophelo bo botle.Ka hona, melaoana e nepahetseng le mehato ea polokeho e tlameha ho ba teng ho netefatsa ts'ebetso e nang le boikarabelo le ho tsosolosoa ha libeteri tsa lithium.