Trommels E ka kopanngoa le limela tse ncha kapa tse seng li ntse li le teng Bakeng sa tsamaiso ea litšila le lisebelisoa tsa ho tsosolosa

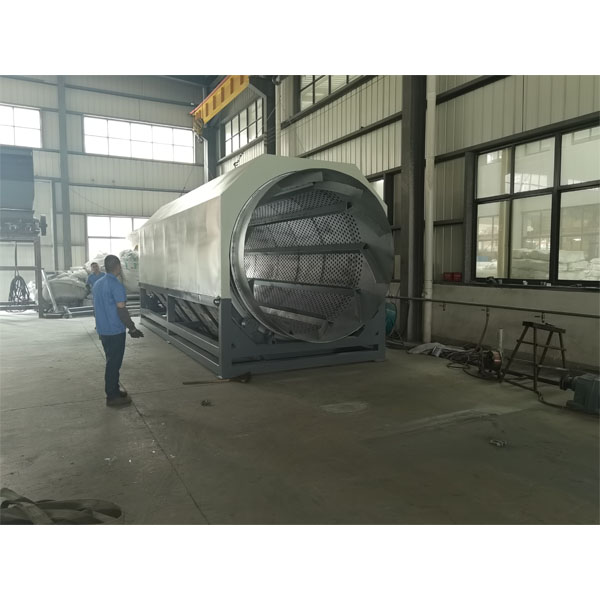

Trommel ke mochini o kang moropa oa cylindrical o sebelisoang liindastering tse fapaneng bakeng sa ho hlopha le ho arola thepa.Joalo ka taolong ea lithōle le litsing tsa ho e sebelisa hape bakeng sa ho hlopha le ho arola lipolasetiki tsa litšila.E na le moropa o pota-potileng oo hangata o nang le pefo kapa meshed, e lumellang likaroloana tse nyane hore li fete ha lisebelisoa tse kholo li bolokiloe.

Ho fepa ka lintho tse bonahalang: Lisebelisoa tsa polasetiki tse litšila li kenngoa ka har'a trommel, hangata ka lebanta la hopper kapa conveyor.Sena se ka kenyelletsa lintho tse fapaneng tsa polasetiki tse kang libotlolo, lijana, liphutheloana le litšila tse ling tsa polasetiki.

Rotating Drum: Moropa oa trommel oa potoloha, hangata o khannoa ke enjene ea motlakase.Moropa o phunyelelitsoe kapa o kenngoe ka li-skrini tsa mesh tsa boholo bo fapaneng, tse lumellang ho arohana ha li-plastiki ho latela boholo ba tsona.

Karohano ka Boholo: Ha moropa o ntse o potoloha, likaroloana tse nyane tsa polasetiki, joalo ka li-flakes tsa polasetiki kapa li-granules, li feta har'a li-perforations kapa li-skrini tsa mesh, ha lintho tse kholoanyane, joalo ka libotlolo tsa polasetiki kapa lijana, li bolokiloe ka har'a moqomo.

Ho hlopha lintho tse bonahalang: Likaroloana tse nyane tsa polasetiki tse fetang ka har'a trommel hangata li lebisitsoe mehatong e tsoelang pele ea ts'ebetso, joalo ka ho hlatsoa, ho qhetsola kapa ho peta.Mekhoa ena e thusa ho lokisa polasetiki bakeng sa ho sebelisoa hape lihlahisoa tse ncha.

Ho tsoa: Lintho tse kholo tsa polasetiki tse setseng ka har'a moqomo oa trommel hangata li lokolloa qetellong ea ts'ebetso.Li ka hlophisoa ka letsoho kapa tsa sebetsoa hape ho tlosa litšila pele li romelloa hore li sebelisoe hape kapa ho lahloa.

Li-trommels tse sebelisoang lits'ebetsong tsa polasetiki tse litšila li ka etsoa ka mokhoa o ikhethileng oa li-drum perforations kapa li-skrini tsa mesh ho amohela mefuta e fapaneng le boholo ba litšila tsa polasetiki.Ke sesebelisoa se sebetsang sa ho arola lisebelisoa tsa polasetiki ho latela boholo ba tsona, tse lumellang ho sebelisoa hape le ho hlaphoheloa ha lisebelisoa.

video:

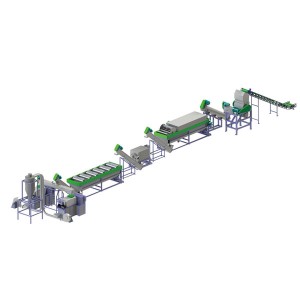

Mochini oa polasetiki o recycleng le oa granulating ke mofuta oa lisebelisoa tse sebelisoang ho khutlisetsa litšila tsa polasetiki ho li-granules kapa li-pellets tse ka sebelisoang hape ho etsa lihlahisoa tse ncha tsa polasetiki.Hangata mochini o sebetsa ka ho petsola kapa ho sila litšila tsa polasetiki hore li be likotoana tse nyane, ebe oa qhibiliha ebe oa li ntša ka lefi ho etsa li-pellets kapa granules.

Ho na le mefuta e fapaneng ea metjhini e nchafatsang ea polasetiki le ea granulating e fumanehang, ho kenyeletsoa screw le li-twin-screw extruder.Mechini e meng e boetse e kenyelletsa likarolo tse ling tse kang li-skrini ho tlosa litšila ho litšila tsa polasetiki kapa mekhoa ea ho pholisa ho netefatsa hore li-pellets li tiisitsoe hantle.Mochini oa ho hlatsoa botlolo ea PET, PP e lohiloeng ka mekotla ea ho hlatsoa mohala

Mechini e nchafatsang polasetiki le ea granulating hangata e sebelisoa liindastering tse hlahisang litšila tse ngata tsa polasetiki, joalo ka ho paka, likoloi le kaho.Ka ho tsosolosa litšila tsa polasetiki, mechine ena e thusa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha polasetiki le ho boloka lisebelisoa ka ho sebelisa thepa e neng e tla lahloa.

Thepa ea li-betri tsa lithium ke mofuta oa lisebelisoa tse sebelisetsoang ho khutlisa le ho khutlisa lisebelisoa tsa bohlokoa ho tsoa libetering tsa lithium-ion, tse sebelisoang hangata lisebelisoa tsa elektroniki tse kang li-smartphone, lilaptop le likoloi tsa motlakase.Thepa hangata e sebetsa ka ho pshatla libeteri likarolong tsa tsona, joalo ka lisebelisoa tsa cathode le anode, tharollo ea electrolyte le lithapo tsa tšepe, ebe li arola le ho hloekisa lisebelisoa tsena hore li sebelisoe hape.

Ho na le mefuta e fapaneng ea lisebelisoa tsa ho nchafatsa betri ea lithium tse fumanehang, ho kenyelletsa lits'ebetso tsa pyrometallurgical, lits'ebetso tsa hydrometallurgical, le lits'ebetso tsa mochini.Ts'ebetso ea pyrometallurgical e kenyelletsa ts'ebetso e phahameng ea mocheso oa libeteri ho khutlisa litšepe tse kang koporo, nickel le cobalt.Ts'ebetso ea Hydrometallurgical e sebelisa tharollo ea lik'hemik'hale ho qhala likarolo tsa betri le ho khutlisa litšepe, ha lits'ebetso tsa mochini li kenyelletsa ho pshatla le ho sila libeteri ho arola lisebelisoa.

Thepa ea ho sebelisa betri ea lithium e bohlokoa bakeng sa ho fokotsa tšusumetso ea tikoloho ea ho lahloa ha betri le ho baballa lisebelisoa ka ho khutlisa litšepe tsa bohlokoa le lisebelisoa tse ka sebelisoang hape ka libeteri tse ncha kapa lihlahisoa tse ling.

Ntle le melemo ea ho boloka tikoloho le lisebelisoa, lisebelisoa tsa ho sebelisa betri ea lithium le tsona li na le melemo ea moruo.Ho fumana litšepe tsa bohlokoa le lisebelisoa ho tsoa libetering tse sebelisitsoeng ho ka fokotsa litšenyehelo tsa ho hlahisa libeteri tse ncha, hammoho le ho theha mekhoa e mecha ea chelete bakeng sa lik'hamphani tse amehang ts'ebetsong ea ho e sebelisa hape.

Ho feta moo, tlhokahalo e ntseng e eketseha ea likoloi tsa motlakase le lisebelisoa tse ling tsa elektroniki e tsamaisa tlhokahalo ea indasteri e sebetsang hantle le e tsitsitseng ea ho sebelisa li-betri.Thepa ea ho sebelisa betri ea lithium e ka thusa ho fihlela tlhoko ena ka ho fana ka mokhoa o tšepahalang le o theko e tlase oa ho khutlisa lisebelisoa tsa bohlokoa libetering tse sebelisitsoeng.

Leha ho le joalo, ho bohlokoa ho hlokomela hore ho sebelisa betri ea lithium e ntse e le indasteri e ncha, 'me ho na le liphephetso tse lokelang ho hlōloa mabapi le ho theha mekhoa e sebetsang hantle le e bolokang chelete e ngata.Ho feta moo, ts'ebetso e nepahetseng le ho lahla litšila tsa betri ho bohlokoa ho qoba likotsi tsa tikoloho le bophelo bo botle.Ka hona, melaoana e nepahetseng le mehato ea polokeho e tlameha ho ba teng ho netefatsa ts'ebetso e nang le boikarabelo le ho tsosolosoa ha libeteri tsa lithium.